Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joints, are essential components used to create watertight and secure connections between concrete pipes in various drainage and sewer systems. These seals play a crucial role in preventing leaks, maintaining system integrity, and ensuring the efficient flow of wastewater or stormwater. Here’s an in-depth explanation of concrete pipe seals, their types, and their benefits:

Types of Concrete Pipe Seals:

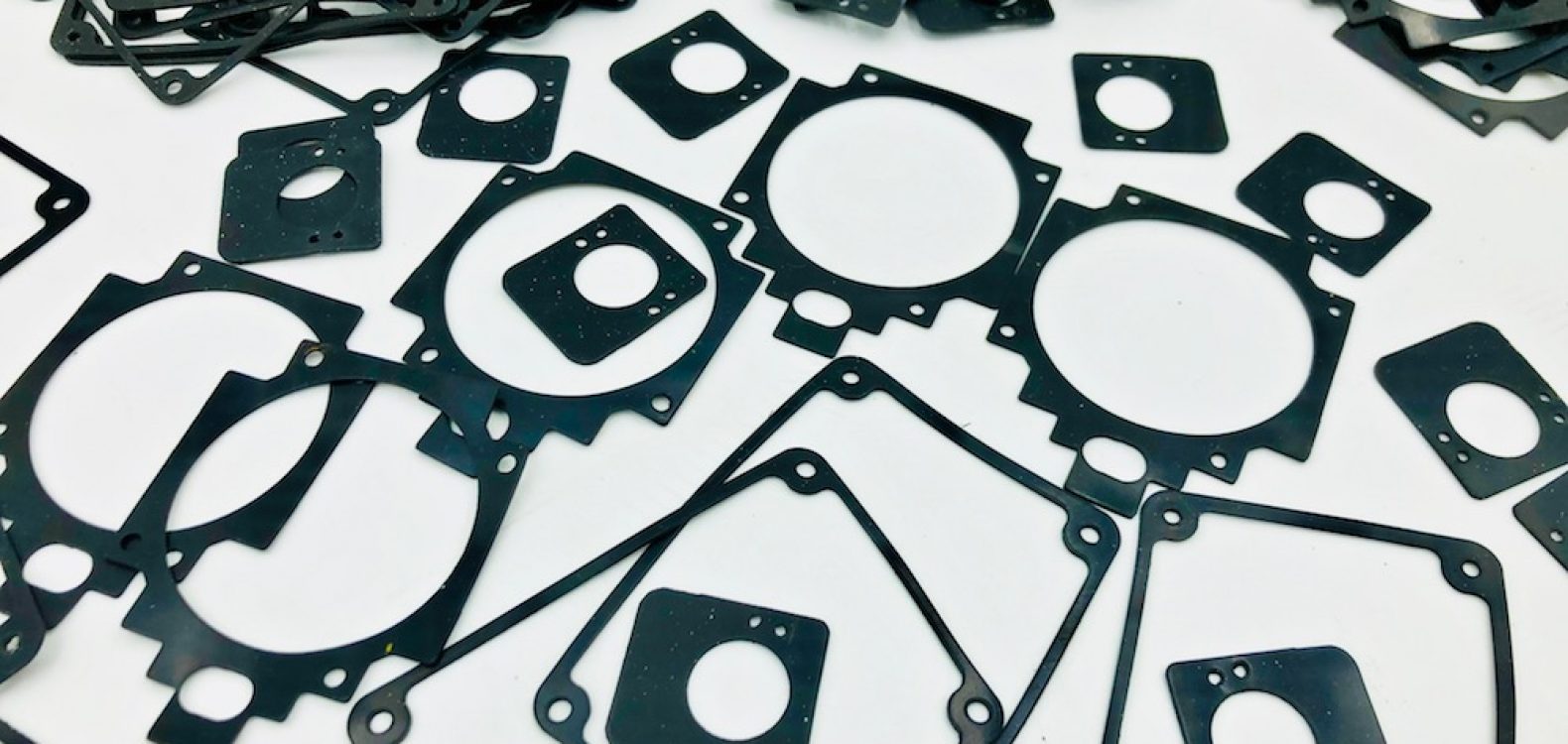

- Rubber Ring Seals: These are one of the most common types of concrete pipe seals. Rubber ring seals are typically made of high-quality elastomers such as EPDM (ethylene propylene diene monomer) or NBR (nitrile butadiene rubber). They are placed in a groove or recess around the spigot (male end) of one pipe, and when the pipes are joined, the rubber ring creates a watertight and flexible seal between the spigot and the socket (female end) of the adjoining pipe.

- Mastic Sealants: Mastic sealants are often used in combination with rubber ring seals to provide additional sealing and bonding properties. Mastic is applied between the spigot and socket to fill irregularities and provide extra protection against water infiltration.

Benefits of Concrete Pipe Seals:

- Watertight Sealing: The primary function of concrete pipe seals is to create a watertight seal between pipe sections. This prevents leaks, groundwater infiltration, and soil erosion.

- Structural Integrity: Seals help maintain the structural integrity of the pipeline by preventing joint displacement or misalignment due to soil settlement or external forces.

- Corrosion Resistance: Many concrete pipe seals are resistant to corrosion, ensuring long-term performance even in aggressive soil or chemical environments.

- Ease of Installation: Concrete pipe seals are designed for easy installation, minimizing labor costs and construction time.

- Flexibility: Rubber ring seals offer flexibility, allowing pipes to expand and contract with temperature variations without compromising the seal.

- Reduced Maintenance: Properly sealed concrete pipes require less maintenance and repair, leading to cost savings over the life of the pipeline.

- Durable Materials: Quality elastomeric materials used in rubber ring seals are durable and long-lasting, ensuring reliable performance.

Applications of Concrete Pipe Seals:

Concrete pipe seals are used in various applications, including:

- Sanitary Sewer Systems: They are employed in sanitary sewer pipelines to prevent the escape of wastewater, preventing contamination of the environment.

- Stormwater Drainage: Concrete pipe seals help manage stormwater efficiently by preventing leaks in stormwater drainage systems.

- Culverts and Water Conveyance: They are used in culverts and water conveyance systems to facilitate the flow of water under roads, railways, or other structures.

- Irrigation: In agricultural and irrigation systems, concrete pipe seals help control the flow of water in irrigation pipelines.

- Industrial Applications: These seals are used in industrial settings where concrete pipes are utilized for the conveyance of chemicals, slurries, or other fluids.

- Underground Utilities: Concrete pipe seals are common in underground utility pipelines for gas, water, and telecommunications.

In summary, concrete pipe seals are essential components in various civil engineering and construction projects. They provide reliable sealing solutions, prevent leaks, and ensure the integrity of concrete pipelines in drainage and sewer systems. Proper selection and installation of the appropriate seal are critical to maintaining the long-term effectiveness of the system.