A “dilatation seal” typically refers to a type of sealing mechanism or device designed to accommodate the expansion and contraction of materials or components due to changes in temperature or other environmental factors. These seals are commonly used in various industrial applications, such as in pipelines, construction, automotive systems, and more, where the need to create a barrier or connection that can withstand temperature variations is crucial.

Here is a more detailed description of dilatation seals:

- Purpose: Dilatation seals are primarily used to address the issue of thermal expansion and contraction in different materials or structures. When exposed to temperature fluctuations, most materials expand when heated and contract when cooled. This can cause stress, leaks, or even structural damage in various applications. Dilatation seals help to mitigate these effects by providing a flexible and effective sealing solution.

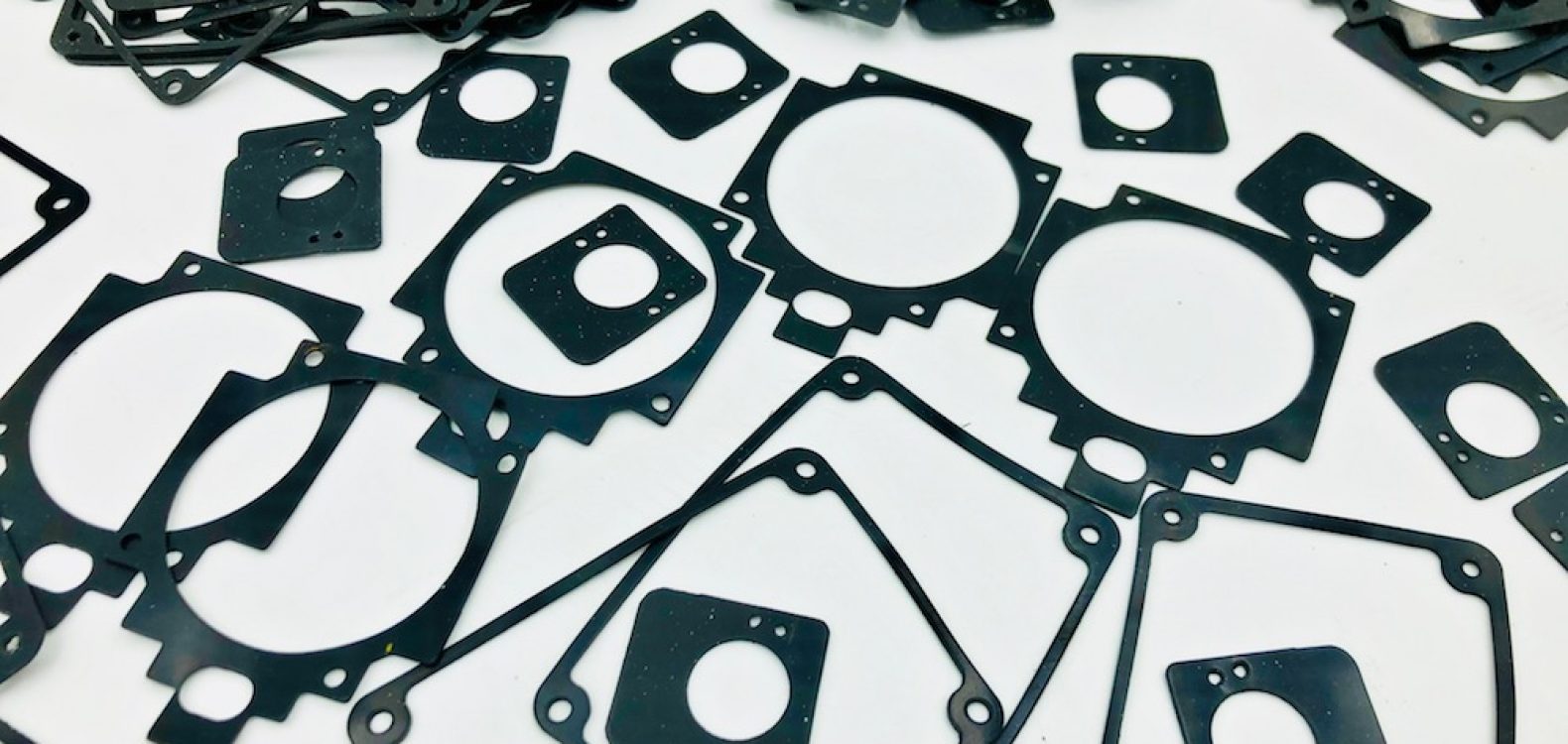

- Materials: Dilatation seals can be made from a variety of materials, including rubber, silicone, elastomers, and even metal alloys. The choice of material depends on the specific application, the temperature range involved, and the type of substances the seal needs to contain or isolate.

- Design: The design of a dilatation seal is crucial for its effectiveness. These seals are often engineered with specific features to ensure they can accommodate expansion and contraction without compromising the integrity of the seal. Common design features include corrugations, bellows, or accordion-like structures that allow for flexibility.

- Applications:

- Pipelines: Dilatation seals are frequently used in pipelines to prevent leakage or damage caused by temperature variations. These seals can be found in various industries, including oil and gas, water distribution, and chemical processing.

- Construction: In the construction industry, dilatation seals are used to accommodate the movement of building materials like concrete, preventing cracks and damage due to temperature changes and settling.

- Automotive: In vehicles, dilatation seals are used in various components, such as exhaust systems, to handle the expansion and contraction of materials caused by heating and cooling cycles.

- Industrial Equipment: Many industrial machines and equipment incorporate dilatation seals to maintain airtight or watertight conditions while withstanding temperature fluctuations.

- Installation: The installation of dilatation seals requires precision to ensure their effectiveness. In many cases, these seals are fitted into gaps or joints, and their design allows them to stretch and compress as needed to accommodate the material expansion and contraction.

- Maintenance: Regular inspection and maintenance of dilatation seals are essential to ensure their continued performance. Over time, the seals may wear or become damaged, which can lead to leaks or reduced effectiveness.

- Customization: Depending on the specific requirements of an application, dilatation seals can be customized in terms of material, size, and design. This customization ensures that the seal can handle the unique conditions of a given situation.

In summary, dilatation seals are critical components in many industries, enabling the reliable containment of materials and structures while accommodating thermal expansion and contraction. Their design and material selection are tailored to specific applications, making them versatile solutions for various temperature-sensitive scenarios. Proper installation and maintenance are key to ensuring the ongoing functionality of dilatation seals in their respective applications.