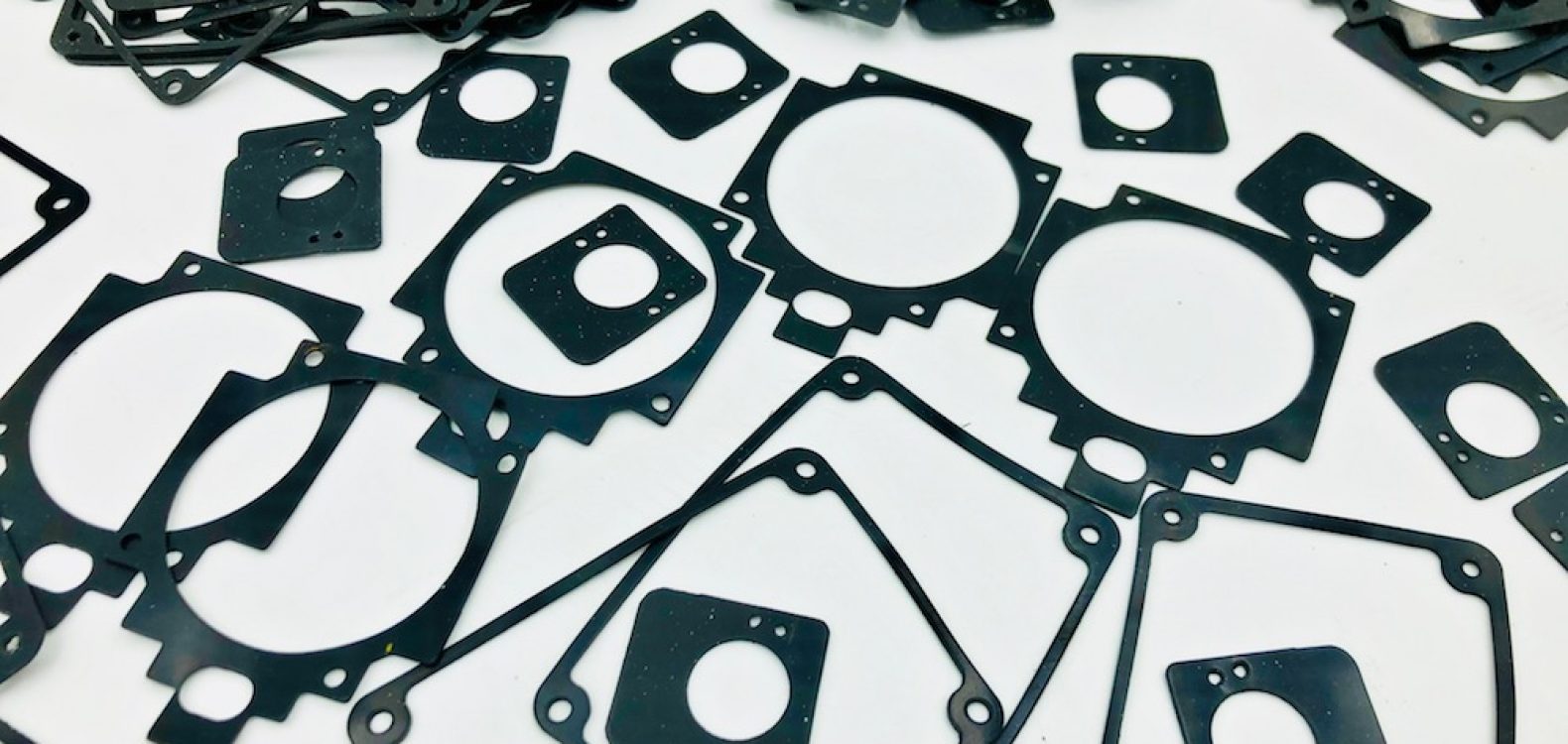

EPDM (Ethylene Propylene Diene Monomer) rubber gaskets are commonly used sealing components made from EPDM rubber material. EPDM is a synthetic rubber known for its excellent resistance to weathering, UV radiation, ozone, heat, and a wide range of chemicals, making it a versatile choice for gasket applications. EPDM rubber gaskets are widely used in various industries and applications due to their durability and flexibility. Here’s more information about EPDM rubber gaskets:

Key Characteristics of EPDM Rubber Gaskets:

- Weather Resistance: EPDM rubber is highly resistant to outdoor environmental factors, including sunlight, ozone, and temperature variations. This makes EPDM gaskets suitable for outdoor and long-term exposure applications.

- Chemical Compatibility: EPDM rubber exhibits good resistance to a variety of chemicals, acids, and alkalis. It can withstand exposure to a wide range of industrial and chemical environments.

- Temperature Tolerance: EPDM gaskets can perform well in both high and low-temperature environments. They can withstand temperatures ranging from -40°C to 150°C (-40°F to 302°F) depending on the specific formulation.

- Flexibility: EPDM rubber is flexible and elastic, allowing it to conform to irregular surfaces and create effective seals, even in applications with slight surface imperfections.

- Excellent Insulation Properties: EPDM rubber has good electrical insulation properties, making it suitable for electrical enclosure gaskets and applications where electrical insulation is required.

- UV Resistance: EPDM gaskets resist degradation and cracking when exposed to ultraviolet (UV) radiation, which is crucial for outdoor applications.

Applications of EPDM Rubber Gaskets:

EPDM rubber gaskets find widespread use in various industries and applications, including:

- Automotive Industry: EPDM gaskets are used for sealing automotive components such as doors, windows, hoods, and trunks. They provide excellent weather sealing and noise reduction.

- Building and Construction: EPDM gaskets are used in the construction of doors, windows, and curtain wall systems to create a watertight and airtight seal, improving energy efficiency.

- HVAC (Heating, Ventilation, and Air Conditioning): EPDM gaskets are used in HVAC systems for sealing ducts, access panels, and other components to prevent air leakage.

- Electrical Enclosures: EPDM gaskets provide electrical insulation and sealing in electrical enclosures and control panels.

- Marine and Boat Manufacturing: EPDM gaskets are used in marine applications for sealing hatches, doors, and windows to prevent water intrusion.

- Industrial Machinery: EPDM gaskets are used in industrial equipment, pumps, and machinery to create seals in various fluid-handling applications.

- Food and Beverage Industry: EPDM gaskets are used in food and beverage processing equipment because of their food-grade properties and resistance to cleaning agents.

- Chemical and Pharmaceutical Industry: EPDM gaskets are employed in chemical processing equipment and pharmaceutical applications due to their chemical resistance.

- Water and Wastewater Treatment: EPDM gaskets are used in water treatment plants and pipes to create reliable seals and prevent leaks.

- Solar Panels: EPDM gaskets are used in photovoltaic (solar) panel systems to provide weather sealing and electrical insulation.

EPDM rubber gaskets come in various shapes, sizes, and profiles to suit specific sealing requirements. They are available as O-rings, gasket sheets, custom-molded seals, and more, making them adaptable to a wide range of applications. Proper selection, installation, and maintenance of EPDM rubber gaskets are essential to ensure effective sealing and longevity.