EPDM (Ethylene Propylene Diene Monomer) rubber seals are commonly used in a variety of industries for sealing applications. These seals are made from EPDM rubber, a synthetic elastomer known for its excellent properties and versatility. Here are some key aspects of EPDM rubber seals:

- Weather Resistance: EPDM rubber is highly resistant to weathering, UV radiation, ozone, and temperature extremes. This makes it suitable for outdoor applications where exposure to the elements is a concern. EPDM seals maintain their integrity and flexibility over time.

- Temperature Resistance: EPDM rubber can withstand a wide range of temperatures, from very cold to high heat, without losing its sealing properties. It remains flexible and doesn’t become brittle in extreme conditions.

- Chemical Resistance: EPDM rubber has good resistance to a variety of chemicals, including acids, alkalis, and polar solvents. This resistance to chemical exposure makes it suitable for various industrial applications.

- Water and Moisture Resistance: EPDM rubber is an excellent choice for sealing applications involving water, moisture, and steam. It has low water absorption properties and maintains its sealing effectiveness in wet environments.

- Electrical Insulation: EPDM rubber offers electrical insulation properties, which make it valuable for use in electrical enclosures, gaskets, and insulating components.

- Automotive Applications: EPDM seals are widely used in the automotive industry for various applications, including door seals, window seals, weatherstripping, and gaskets. They provide excellent sealing and durability, which is crucial for automotive components.

- HVAC Systems: EPDM rubber gaskets and seals are used in heating, ventilation, and air conditioning (HVAC) systems to create airtight seals for ductwork, pipes, and connections, ensuring efficient system operation.

- Construction: EPDM rubber is used in construction for sealing applications in roofing, glazing, expansion joints, and curtain walls. It helps maintain airtight and watertight seals in building structures.

- Marine and Boating: Due to its resistance to saltwater and weather conditions, EPDM seals are used in marine applications to create watertight seals on boats, ships, and docks.

- Industrial Equipment: EPDM gaskets and seals are applied in various industrial equipment, such as pumps, valves, and machinery, to provide sealing and insulation solutions.

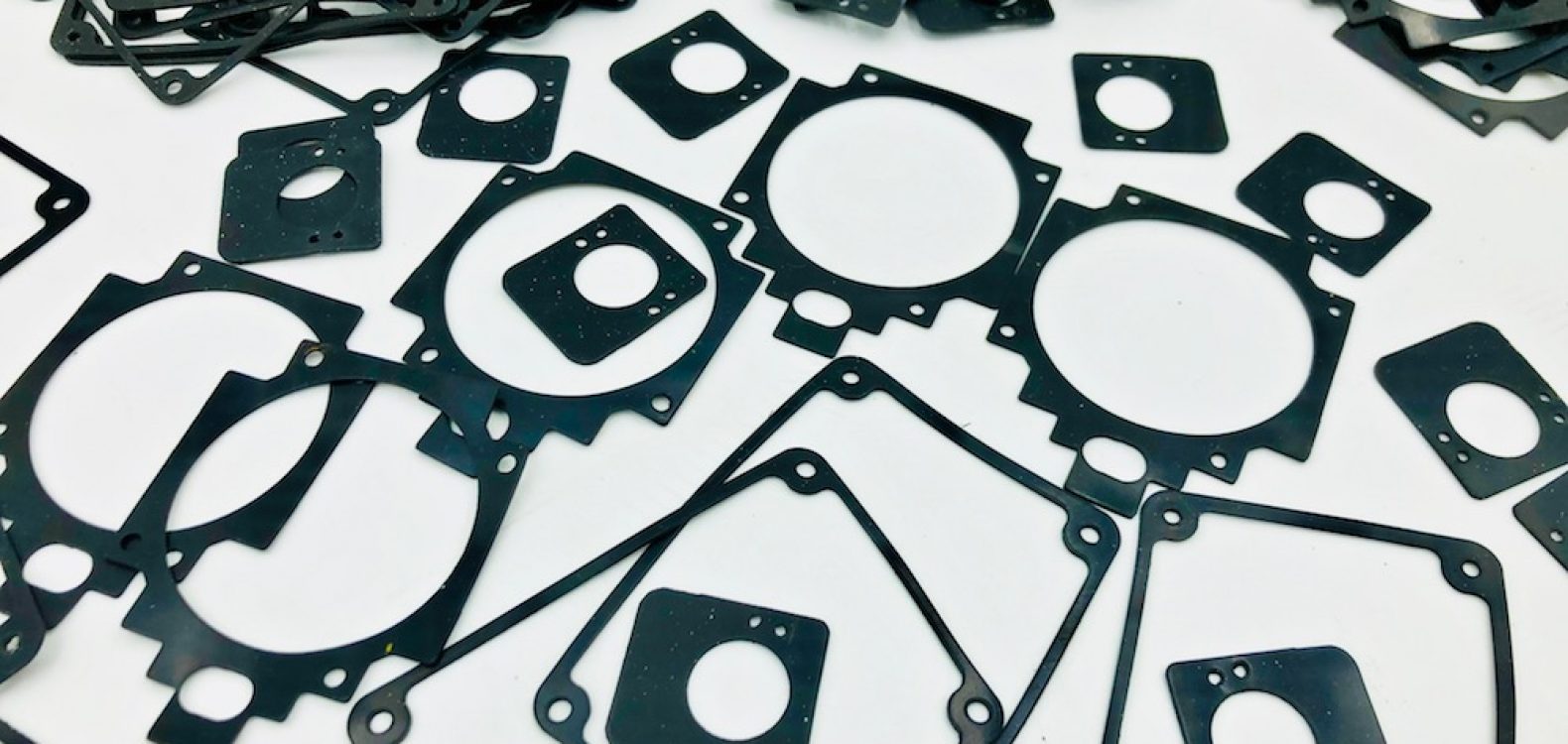

EPDM rubber seals come in a range of shapes and sizes, including O-rings, gaskets, strips, and custom-molded profiles, allowing them to be tailored to specific sealing needs. They are a versatile choice for sealing solutions in diverse industries, offering a combination of durability, flexibility, and resistance to environmental factors.