Certainly, here’s a comprehensive and detailed description of a rubber gaskets and seals factory, highlighting its key components, processes, operations, and the significance of such facilities in modern industrial production:

Introduction to a Rubber Gaskets and Seals Factory:

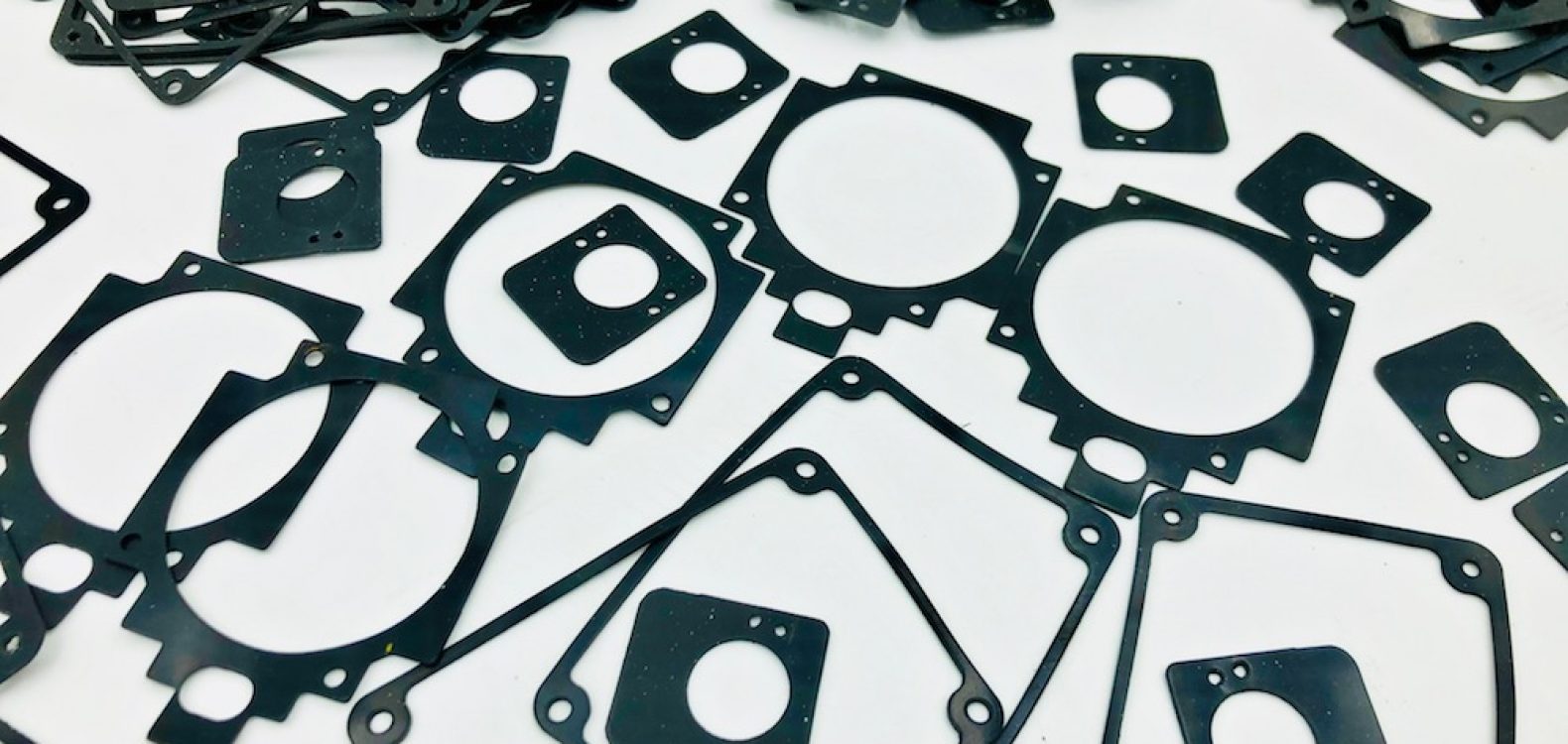

A rubber gaskets and seals factory is a specialized manufacturing facility dedicated to the production of a wide variety of rubber-based sealing solutions. These factories play an indispensable role in supplying critical components that are essential for maintaining the integrity of mechanical systems in various industries. They are equipped with cutting-edge machinery, skilled labor, and stringent quality control measures to ensure the production of high-quality gaskets and seals that meet the diverse needs of industries worldwide.

Key Components and Infrastructure:

- Production Area: The heart of a rubber gaskets and seals factory is the production area, which houses various machines and equipment for the manufacturing process. This area is often organized into sections for different types of gaskets and seals, such as O-rings, flat gaskets, and extruded seals.

- Raw Material Storage: Factories stock a wide range of rubber compounds and elastomeric materials, each chosen based on specific application requirements. These materials are stored in controlled environments to preserve their quality.

- Tooling and Die Manufacturing: Tooling and die-making facilities are crucial for creating molds, dies, and tooling needed for shaping and cutting rubber materials into the desired gasket or seal profiles.

- Quality Control Laboratory: A dedicated quality control laboratory is essential to ensure the produced gaskets and seals meet stringent quality standards. It includes equipment for material testing, dimensional inspection, and performance testing.

- Packaging and Shipping Area: Once gaskets and seals are manufactured and inspected, they are packaged according to customer specifications and prepared for shipping.

Manufacturing Processes:

A rubber gaskets and seals factory employs several essential processes to transform raw rubber materials into finished sealing products:

- Material Preparation: Rubber compounds are selected based on application requirements and mixed with curing agents and other additives. This mixture is then processed into sheets or strips.

- Cutting and Shaping: Rubber sheets are cut into the desired shapes using cutting machines, and seals are formed through processes like die-cutting or extrusion. Tooling and dies are customized for specific seal profiles.

- Vulcanization: The shaped gaskets and seals are subjected to vulcanization, a heat-treatment process that enhances their properties, including hardness, elasticity, and chemical resistance.

- Quality Assurance: In-process inspections and rigorous quality control measures are applied at every stage to ensure dimensional accuracy, material integrity, and adherence to industry standards.

- Secondary Operations: Some seals may undergo secondary operations, such as adhesive application, printing, or assembly with other components, to meet customer requirements.

Environmental Considerations:

Rubber gaskets and seals factories often implement eco-friendly practices to minimize their environmental impact. This may include recycling rubber waste, using energy-efficient equipment, and adhering to environmental regulations governing emissions and waste disposal.

Significance and Applications:

Rubber gaskets and seals are critical components across a wide array of industries, including automotive, aerospace, construction, healthcare, manufacturing, and more. Their sealing properties are essential for preventing leaks, maintaining pressure, and ensuring the functionality of various mechanical systems. A reliable and well-equipped rubber gaskets and seals factory is instrumental in supporting these industries by supplying high-performance sealing solutions.

In conclusion, a rubber gaskets and seals factory is a sophisticated manufacturing facility with specialized processes and equipment dedicated to producing essential sealing components. These factories contribute significantly to industrial progress by ensuring the integrity and efficiency of mechanical systems across diverse sectors, ultimately benefiting society through improved product quality and safety.